Technology

Research & Development

Continuous efforts for meeting client’s requirements, Innovatively

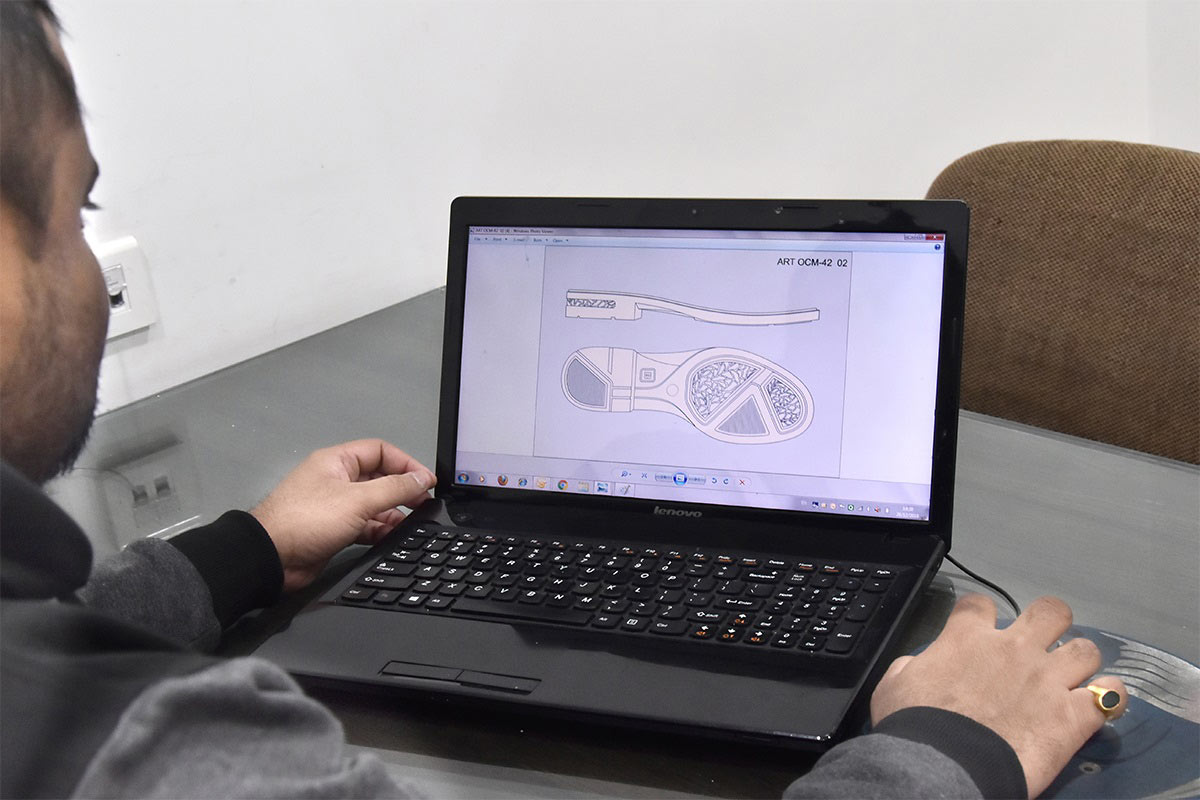

The state-of-the-art technology is available to aid in successfully completing each project and developing new products. This includes, but not limited to, CAD design software for the design of soles, a laboratory for testing chemical properties of Polyurethane and finished soles and CNC machine to produce wooden maquette of sole design. Deep research on upgrading available technologies and bringing the new one is a continuous process at Airysole.

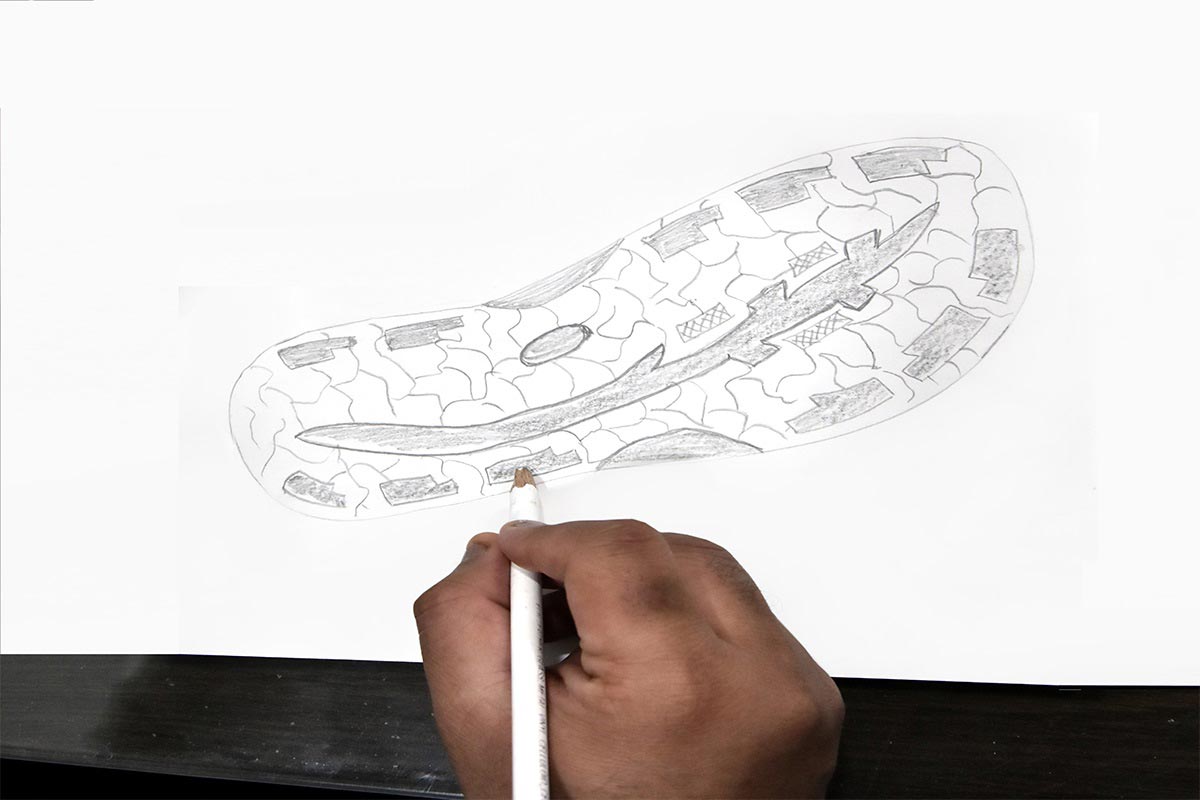

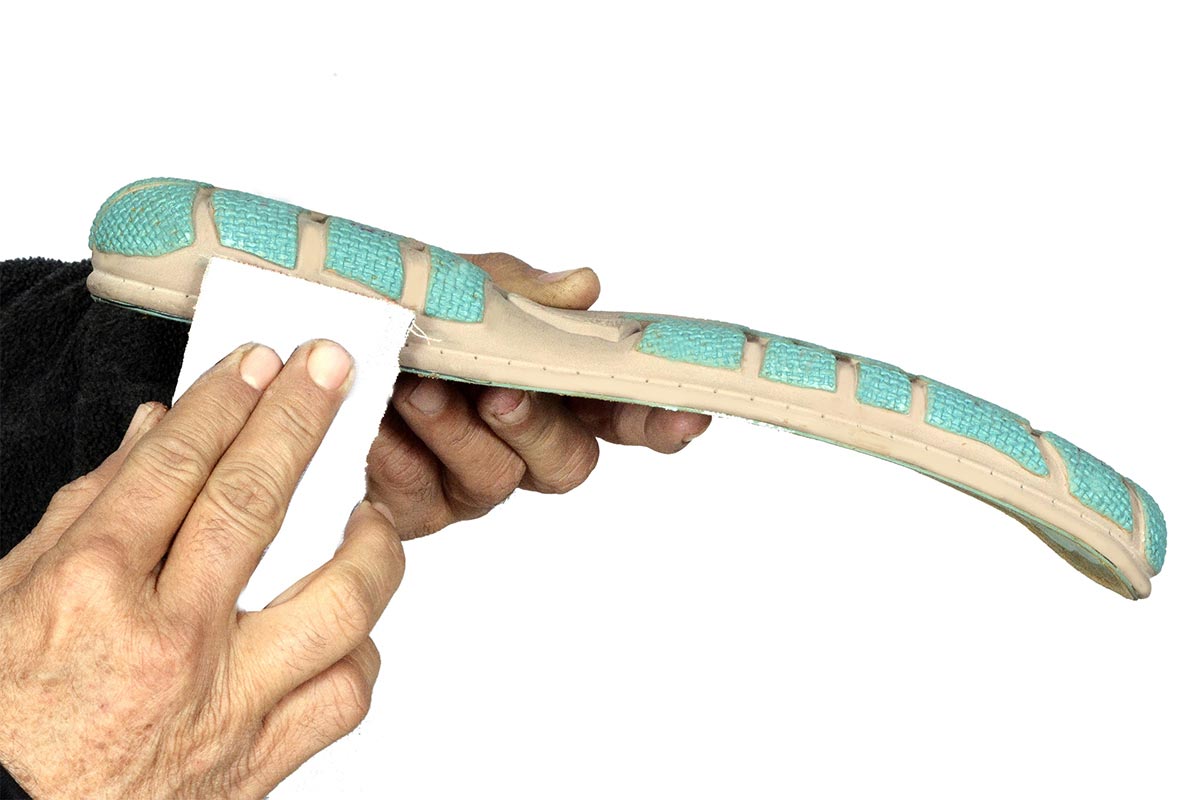

Our R&D team consists of qualified engineers, chemical analysts and designers enjoys many years of scientific and practical experience in the area of footwear technology. Using their deep knowledge and expertise, our sole experts execute each project activity - from sketching to sample development of soles- with dedication in order to make it ready for production in a very short span of time.

Production

Fulfilling our client’s regular and urgent orders, On time

We have 5 production lines in 2 business units equipped with the latest Italian machineries, having annual capacity to produce 4.5 million pairs of PU soles. This includes,

- Fully automatic Pumix rotary moulding machine

- Semi automatic Pumix banana moulding machines,

- Washing machines

- Spray machines

- Lean Assembly Line

Apart from it, our in house collection of moulds of more than 600 sole designs makes the sample development process very fast.

Our production team consists of planning engineers, supervisors and highly skilled labors, who are excellent at their job of executing the entire order to meet the delivery schedules. Apart from regular, ‘urgent order fulfillment on time’ is what makes us ahead of our competitors. We take extreme care at each juncture of production to ensure that the quality of our finished soles matches with the best in the industry.

Quality Control

Exceeding customer’s quality expectations, Everytime

We have a dedicated quality control department equipped with Bennewart and Bata belt flex testing machines, abrasion tester and chemical laboratory. Our quality control team works in coordination with the production team to ensure desired quality in finished products meet client’s expectations.

We undertake following tests regularly during the production and before the finished goods leaves our factory in order to deliver the soles with the most complete features: strength, flexibility, durability, comfort and safety.

- Raw Material Testing

- Flexibility Testing of Soles (Bennewart / Bata Belt Testing Machines)

- Abrasion Testing

- Color Adhesion Testing

Tell us your requirements of PU Soles

Whether it is urgent or complex, we promise to deliver it on time

INQUIRE NOW